1. Client request

Thorough and accurate entry of input information leads to accurate results. Therefore, we try to specify this most important phase with the client as precisely as possible.

2. Submission of documentation

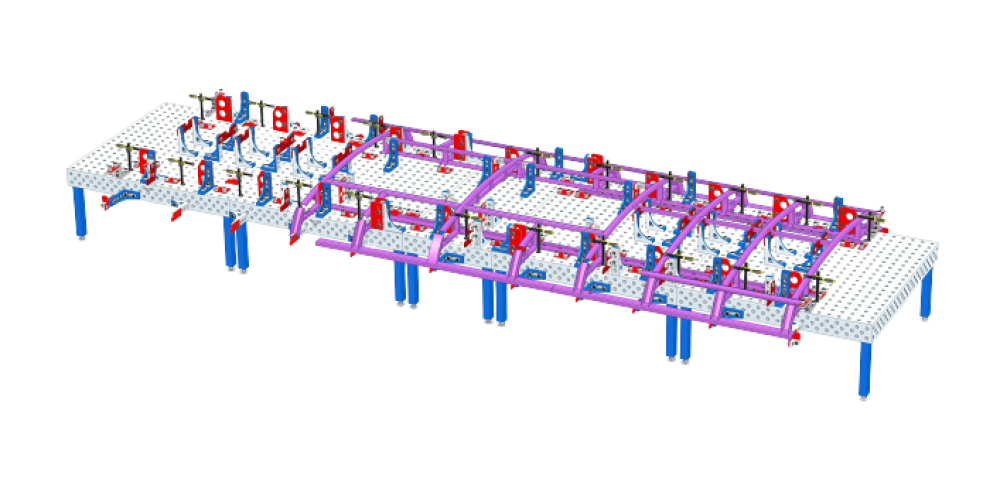

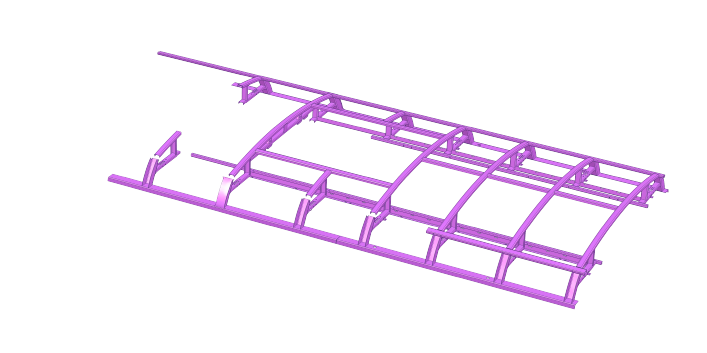

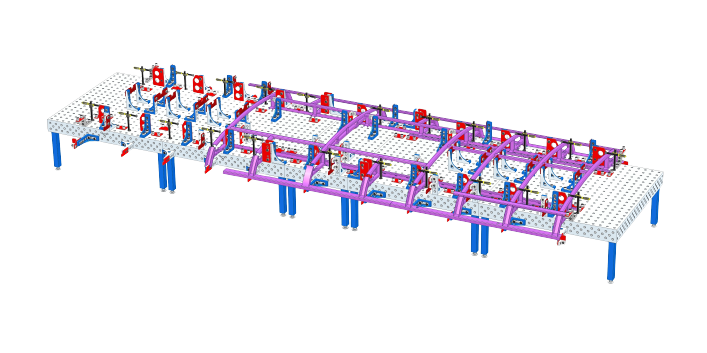

We design the final solution with the help of a 3D CAD program and therefore we prefer submission in the form of 3D models.

3. Project processing

The project is consulted with the client during processing so that the client has an overview of its progress at all times. Each project begins on a blank sheet of paper. Processing times therefore differ from case to case.

4. Presentation

The offer is submitted in written form with an exact list of items. At the request of the client, it is possible to make a presentation on site with interested workers and a sample of the project in a 3D presentation.

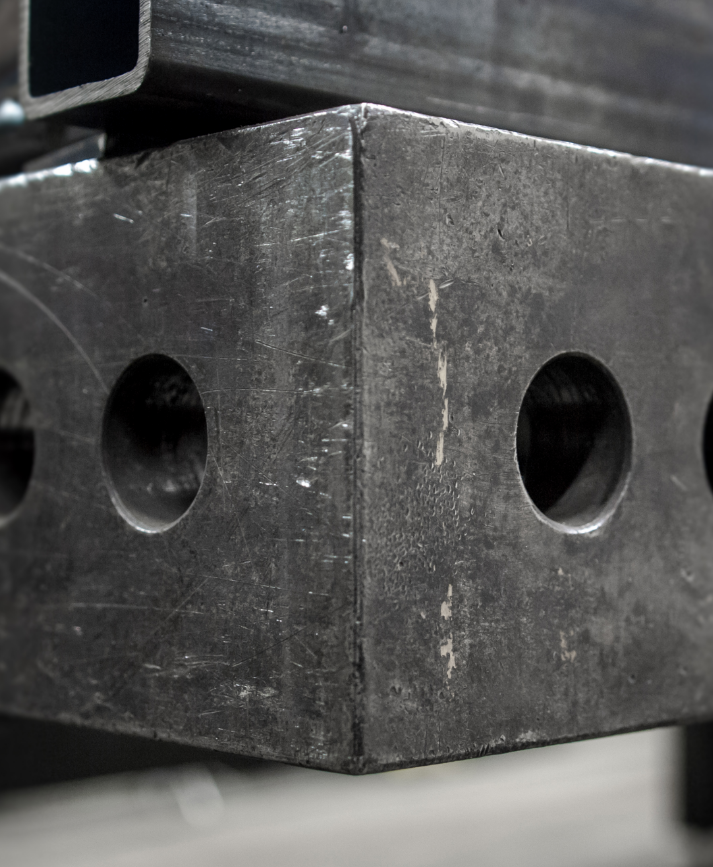

5. Delivery, assembly, tuning

Assembly of more complex assemblies at the point of use is a matter of course. Debugging and getting to know the correct use is also taking place.

6. Service, support

Expansion, possible quick change of product is very simple and our employees are always ready to help with implementation.

7. Feedback

We are interested in the result of our work. That is why we remain in touch with the client even after the end of the project.