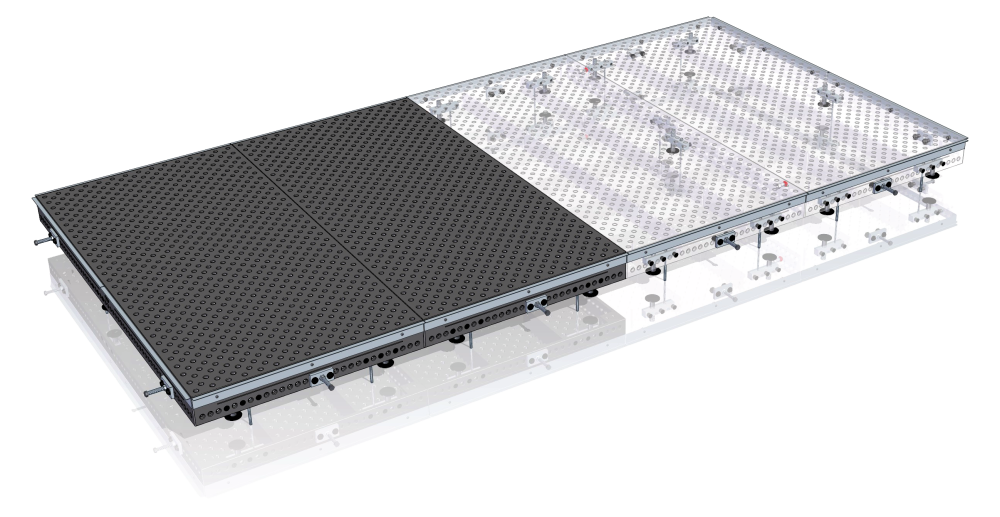

The floor is highly versatile and reusable. It can be applied in facilities requiring prototype stations, welding kit systems, and movable testing areas. It is also suitable in conjunction with rotary platforms, painting and other robots, scanners, etc. By placing the handling surface in the floor plane, this system is also suitable for heavy and demanding fixtures, such as in the automotive industry.

- The floor consists of floor clamping plate systems.

- Kit components are used to connect and rectify standard Siegmund welding tables, which can be assembled into units several tens of meters long.

- The floor, like the kit systems, is manufactured in three dimensional series of system holes: 16 mm (System 16), 22 mm (System 22), and 28 mm (System 28).

- The clamping floors can be assembled above the level of the surrounding floor or at the level of the surrounding floor.

- All rectification and demarcation systems of the floor can be height-adjusted after installation.

- The advantage of the solution is the possibility of using standard Siegmund welding tables, which, together with kit components for joining and rectification, reduce the time and financial requirements for the overall implementation of the clamping floor.

- Several types of surface finishes can be applied to the floors, increasing their lifespan.