Custom design

and engineering work.

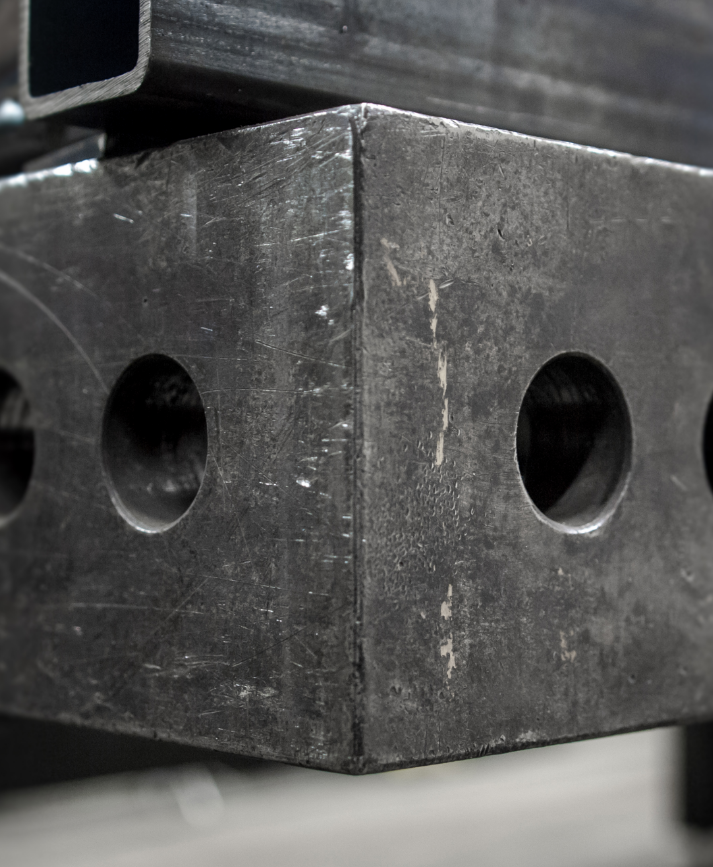

Custom project and design work. Preparation of individual fixtures and solutions in the field of welding, metal machining, and other engineering production.

Custom project and design work. Preparation of individual fixtures and solutions in the field of welding, metal machining, and other engineering production.

Thorough and accurate input of information leads to precise results. Therefore, we strive to specify this most important phase with the client as accurately as possible.

We propose the final solution using a 3D CAD program and thus prefer input in the form of 3D models.

During the project processing, we consult with the client to ensure they have an overview of its progress. Each project starts with a blank sheet of paper, and processing timelines vary from case to case.

The offer is presented in written form with a precise itemized list. If requested by the client, a presentation can be conducted at the client's location with involved staff, including a demonstration of the project in a 3D presentation.

Expansion or potential rapid modification of the fixture is straightforward, and our employees are always ready to assist with implementation.

The installation of more complex assemblies on-site is a standard procedure. Subsequently, fine-tuning and familiarization with proper usage take place.

We are interested in the outcome of our work. Therefore, we maintain communication with the client even after the project is completed.