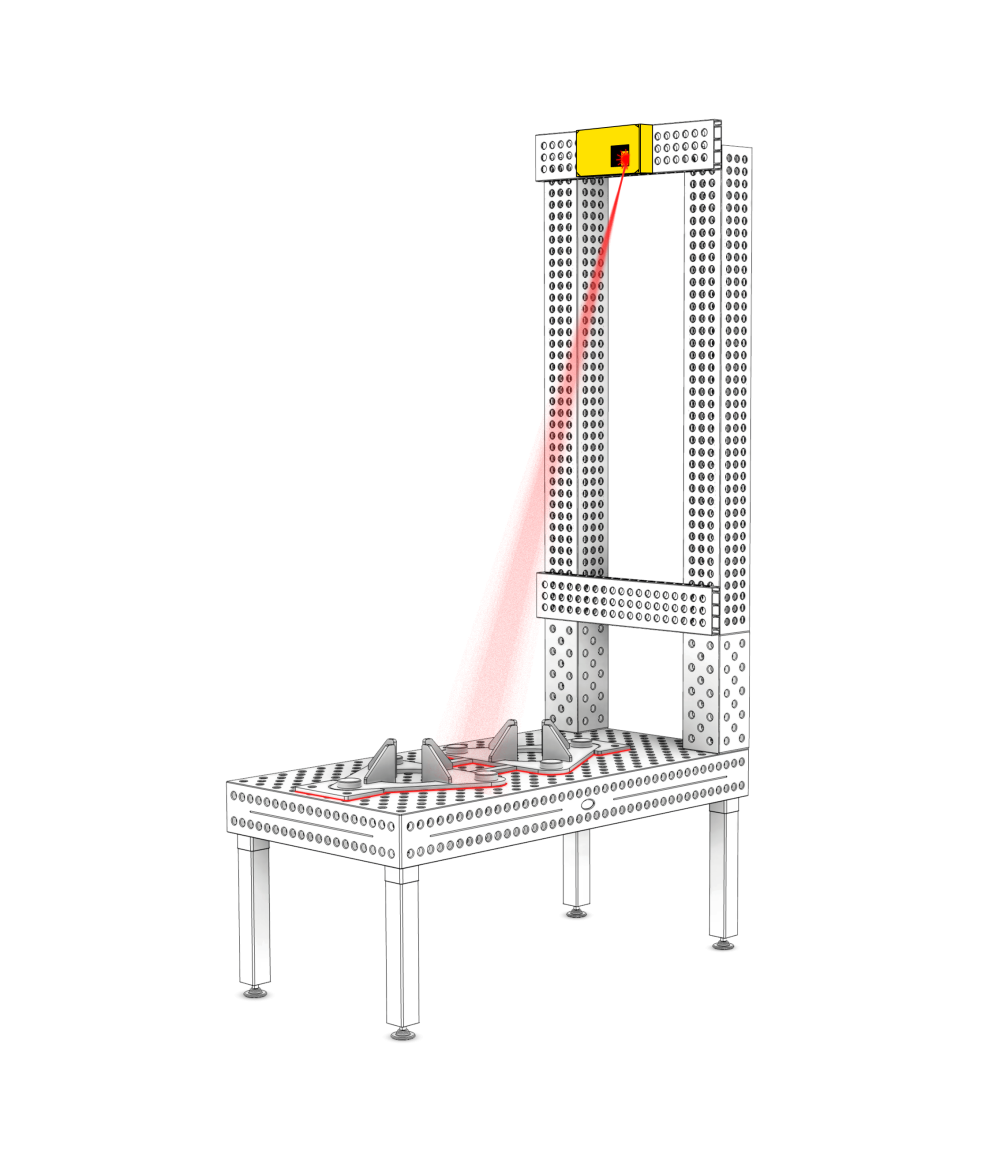

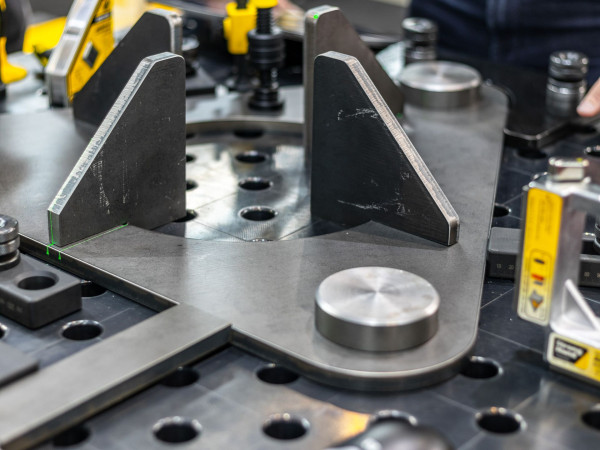

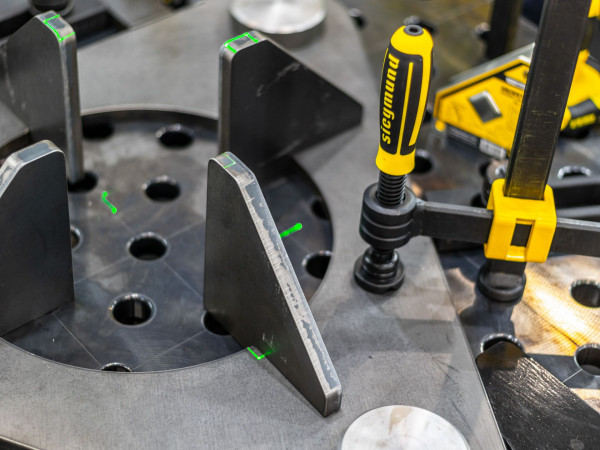

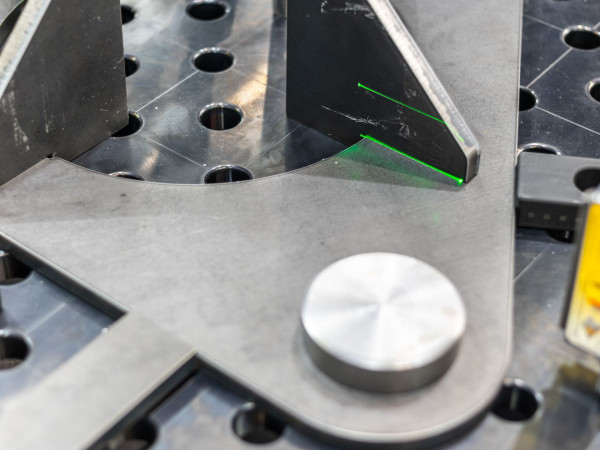

The laser lines are created using a CAD model, which allows the system to project the outline of desired parts, artifacts, or areas. The result is a virtual and collaborative 3D template that enhances a wide range of assembly and manufacturing applications. The technology of virtually projected templates eliminates the need for physical templates and fixtures.

Advanced trajectory control

Provides fast projection with excellent dynamic accuracy and rapid refresh rate, minimizing laser flickering that occurs with other projection systems.

Precise adjustable projection with long range

Variable depth of focus allows projection at various distances ranging from 1.83 m to 15.25 m.

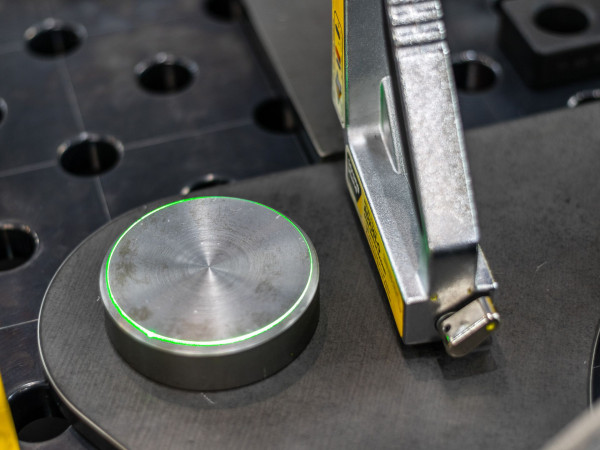

Reference retro-reflective markers

Photogrammetric markers (minimum of 6) are used to achieve optimal alignment of the projected image onto a surface or object. The projected image is thus identical to the CAD model.

Collaboration with multiple projectors

For large structures or in spatially constrained areas, multiple TracerM projectors can be used, controlled from a single computer, providing extensive virtual models in one coordinate system.

Reliable solution

This is a proven technology designed for use in manufacturing environments, thanks to its dustproof construction.

Benefits

- Elimination of physical templates and fixtures.

- No workplace preparation, saving time and enabling quick deployment in existing production conditions.

- Direct transition from CAD model to virtual template. Reduction of financial costs associated with the production and storage of physical templates and fixtures.

- Reduction of defects and rework. Improvement in quality and performance.

Industry and Applications:

|

Composite Materials

|

Automotive Industry

|

|

Aerospace Industry

|

Other Industries

|