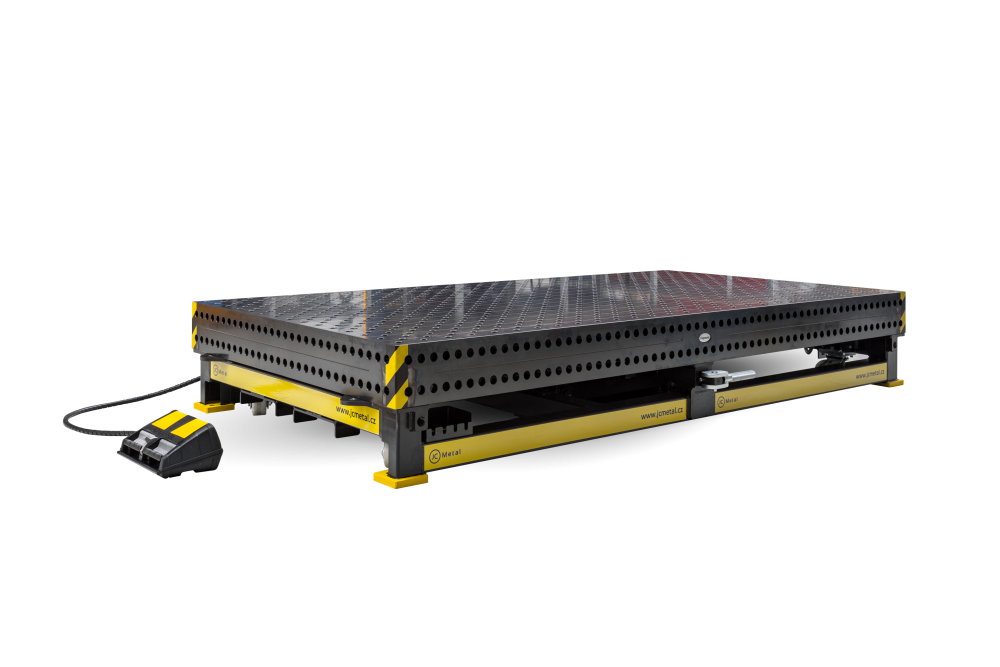

The rotary platform consists of a fixed part with extendable rolling wheels and an extendable part with a rotating device on which a reinforced plasma-nitrided welding table Siegmund is attached.

The extension of the rolling wheels and the extendable part of the trolley is performed by hydraulic cylinders operated by a foot-operated hydraulic pump powered by compressed air.

The rotation of the welding table is performed manually by the operator after extending the rotating part from the locked position. Rotation can be performed within a range of 360°, and the table can be mechanically locked in predetermined basic positions or at specified intervals.

The working surface of the welding table can be expanded using original Siegmund accessories, which can be clamped to the sides of the table. The entire system can also be equipped with a set of original Siegmund clamping accessories, which can be supplemented as needed.

The support frame of the rotary mechanical trolley allows the anchoring of the entire device to the Siegmund steel clamping floor with a system of Ø 28 mm holes spaced at 100×100 mm intervals, so that the device can be repeatedly secured in the desired positions when moving within the clamping floor.

The retractable castor wheels are used for device relocation. The relocation can be done manually or with the help of a forklift truck.